Material covered by this specification forms a waterproofing system to be applied to selected areas of a bridge substructure.

.All substructure waterproofing systems intended for use under this specification must be prequalified. Submit a written request to the Bureau Chief of Construction and Materials, with the following information for each type and brand name being offered.

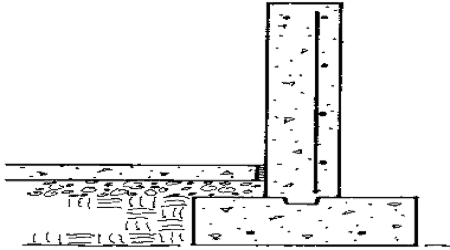

Substructure Waterproofing system provides a “protected membrane” system which usually incorporates a drainage board. Is fully bonded to the “POSITIVE” side of the structure, usually concrete and covered with an IKO Plasdrain drainage board and then structural concrete, backfill etc to suit performance criteria.

Substrate Waterproofing designs often includes the vertical surface of external walls of underground car parks and storage areas. A vertical drainage board is recommended to provide drainage and protection for the vertical waterproofing. A drainage system should be incorporated at the base of the wall to allow for the free flow of any water build up in the ground.

Sub Structure Membrane System

Sub Structure Membrane System

Introduction

This Chapter provides guidance on the requirements associated with the design and construction of basements and other below ground structures. Principally, this concerns the process by which the risk of ground water penetration is appraised and addressed, so that problems associated with penetration do not occur while consideration is also given to economic construction. This process and rationale is primarily detailed within BS 8102 (2009) Code of Practice for protection of below ground structures against water from the ground (and other associated design guides). However, further practical guidance on this and compliance with warranty requirements is included herein.

General principle

General principle of waterproofing design The approach detailed within BS 8102 involves assessment of a given site to determine the characteristics which influence risk. With the benefit of knowledge gained through this investigation and assessment, suitable designs for dealing with ground water, gases and contaminants can then be devised and constructed.

Design responsibilities

Design responsibility Production of a suitable design is one of the most important aspects in achieving a successful outcome, where the required standard of environment is created within the basement space and maintained in the long term. A common assumption in waterproofing is that workmanship is the most ‘critical factor’ and while this is undeniably important, the highest standards of workmanship will not make up for inadequate design, and hence correct design is the first step in achieving the desired outcome. To this end, BS 8102 includes a section regarding ‘design team’, which states that the advice of a Geotechnical Specialist be sought for assessment of the Geology and Hydrogeology and that a Waterproofing Specialist be included as part of the design team from the earliest stages, so that an